Printondemand-worldwide ‘disrupts’ the market!

Screen inkjet delivers quality that Cork has dreamt of

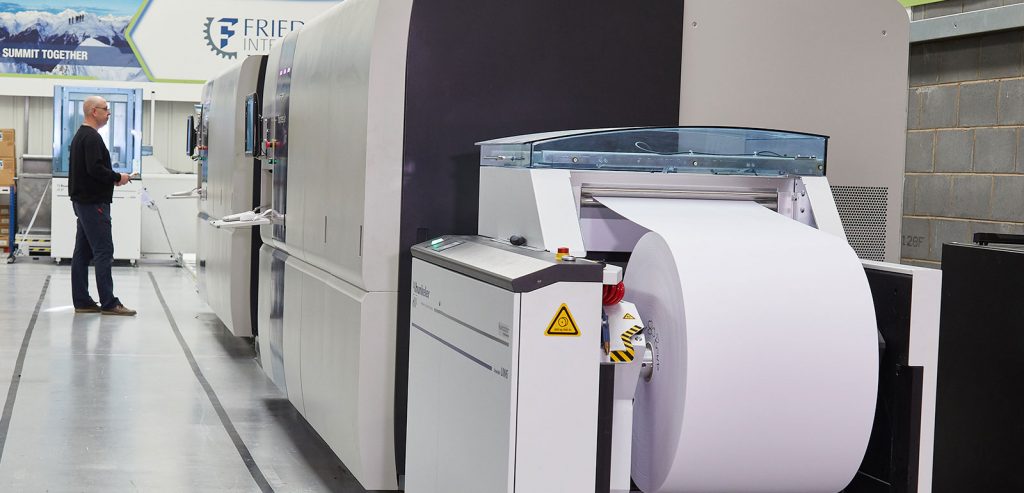

Printondemand-worldwide achieves disruption in the book market with manufacturing model based on the quality the Screen TruepressJet 520 SD delivers.

The publishers that Printondemand Worldwide work for have signed off on the print quality that its Screen TruepressJet 520 HD delivers. It paves the way for the Peterborough company to achieve the disruption in the book market that the printer has been targeting.

The piezo inkjet press was star of an open house for Screen, Hunkeler and Muller Martini customers and prospects from across the UK & Europe last week. The audience of printers were invited to pick the difference between inkjet, cut sheet toner and offset litho print on samples of the same job. The majority failed, as publishers had done when asked to make the same choice.

It is changing perceptions of what the technology is capable of. CEO Andy Cork says that one publisher agreed to talk with him, but banned any mention of inkjet, the perception being that too many printers are talking up a technology that could not deliver the quality needed. Instead he says he discusses the benefits of print run of one, the choice of substrates and cost. Then he might mention it being printed on the Screen inkjet press.

The quality breakthrough comes as a result of Screen’s SC inks. These contain a polymer which becomes the bonding agent allowing the high pigment ink to adhere to standard offset papers without a pre or post print coating. And the press runs at up to 150m/min, equivalent to a B2 litho press running at 15,000sph.

“We couldn’t really offer high quality and a full range of substrates before. We the SC inks that changes,” says Bui Burke, Screen Europe’s senior vice president sales. “”Digital is now able to cater for a huge part of the market.”

For Cork, the quality and automation that the company can now deliver fulfils a long held dream. “We have been trying to disrupt the market place, by being able to produce a book of one in colour that is the equivalent of litho, and at the right price.”

The ability to print on standard papers provides the breakthrough. An inkjet paper can cost up to £1,100 a tonne and with an extended order period; a litho paper will be £650 a tonne and much easier to obtain. And the experience for the reader is not changed. “Before inkjet paper always looked and felt different. Now you cant really tell the difference between inkjet and litho,” he says. Publishers can print an initial run litho and can switch to inkjet for the top up orders.

The automation comes with an inline link to a Hunkeler BookLine. While this is capable of producing six page signatures, PoD has it set to run four-page folds continually. This avoids time sapping changes to the set up. It is the first line in the UK with Hunkeler’s DynaCut technology. This adjusts on the fly to trim each book format precisely so that the printer can change on the fly without wasting paper at the head and tail of a book. The fore edge trim is the only waste generated as all books are imposed from the central spine.

Books then pass to the binding line, a conveyor feeding a Muller Martini Vareo and Horizon BQ470 for binding and then to a Muller Martini Infinitrim to automate the final element of finishing. A single book is as easy to produce as a batch of a dozen or more.

The limitation is that PoD Worldwide runs only six grades of paper, but as these include silk and gloss coated substrates, there is little to limit the publisher. It can produce up to 7,000 books a day in this way “from one to 2,000 copies” says Cork.

Many are produced for mainstream trade and STM publishers; others are printed for self publishers, sometimes with surprising results. “One was book on dustcarts which we thought would have limited appeal, but it has sold thousands of copies,” he says. These can be promoted through the Great British Bookshop, a more parochial version of Amazon, that is part of the group approach. “We want a margin from across the whole supply chain,” he adds.

A tie up with US distribution giant Baker & Taylor is making POD’s books to an audience in the US. “There are 750,000 titles in the Book Vault,” its digital repository he says. “We can supply that content globally.”

Orders can be supplied same day, overnight, at three- or five-day intervals. Cork says that 25% specify next day delivery. Software is used to manage the flow of work to avoid an on rush of work that can result in unwanted over time and the pressure that can lead to mistakes, reprints and cost.

The journey towards lean automated manufacturing of books has to date taken a 21-stop production process down to eight stages. Cork is pressing to reduce that still further, reducing the cost of production still further. There is the matter of what are described as the ‘uglies’. These are the products that are wire bound, case bound or of out of normal formats that have to be produced in a semi manual way. And while inkjet has reached the point it has, 10% of books are printed on the cut sheet machines.

“The story is not about inkjet. It’s about disrupting the market place. we are producing a quality book at a low unit price and if the end customer thinks it’s right, it’s right.”

Bookvault

Bookvault Photobubble

Photobubble BookWIZARD

BookWIZARD